- Matting Accessories

Click on an accessory to view

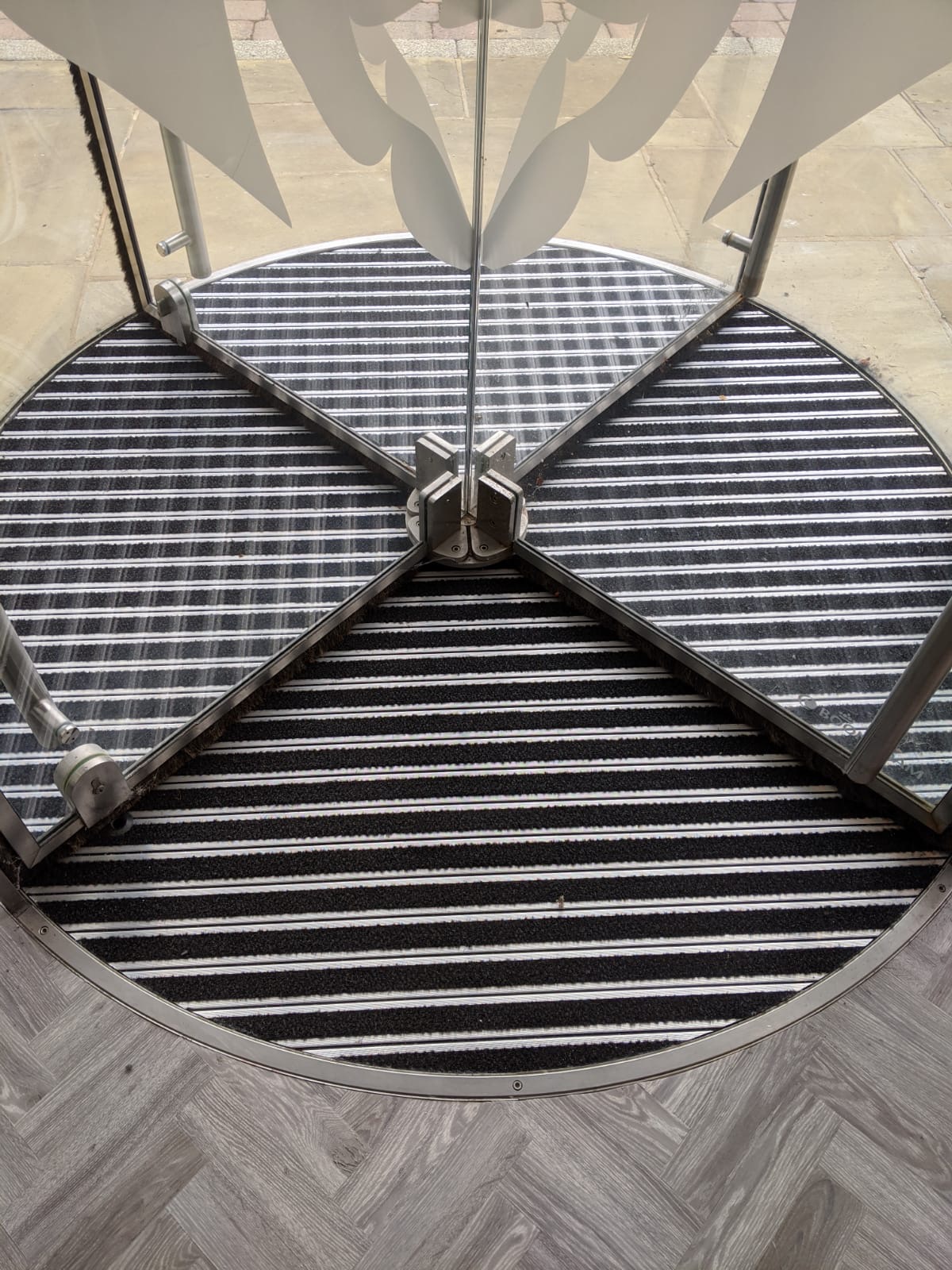

- Matwell Frames

- Description of product

- Formable Frames

- Description of product

- Ramp Section

- Description of product

- T Section

- Description of product

Primary Matting

Product Selection Specified for internal and external applications to form a protective barrier against the ingress of dirt and moisture at entranceways. Primary matting will usually comprise a combination of materials to perform scraping and wiping functions for the capture of foot-borne moisture, dust and debris. Primary matting is manufactured in either open or closed construction.

Open Construction

Usually specified for external applications and exposed entranceways; provides spaces for dirt and moisture to fall through the matting into the matwell base. Open construction is the preferred choice where a frequent cleaning service cannot be provided.

Closed Construction

Ideal for internal applications where a regular cleaning regime is in operation. Foot-borne moisture, dirt and debris is captured on the 'closed' matting surface for convenient removal by vacuum cleaner.

Secondary Barrier Matting

UKM Barrier Carpet is available in two forms, tufted pile and needlepunch fibre bonded construction. Secondary matting is often used in conjunction with a primary system to provide further protection into the building. This high performance carpeting is ideal for reception foyers and other high traffic areas.

Tufted Pile

Tufted Pile Matting will capture a large amount of moisture, dust and dry debris. The open fibre construction ensures fast evaporation of moisture and provides excellent airflow for efficient vacuum cleaning. The tufting process accommodates any special pattern and colour-matching requirements.

Needlepunch Fibre Bonded

Fibre Bonded Matting has a close formed 'pile', is coarse in nature and provides a high level of scrape action at the surface. The fibre bonding process enables high volume manufacturing, a significant factor in its comparative cost against tufted products. The material is exceptionally hardwearing.

External Matting

It is not recommended that materials which absorb or retain water, be specified for external use in areas where frost may occur, as this may cause the surface to become slippery underfoot in certain conditions.

Chandos Street Shaw, Oldham, OL2 8AZ

Chandos Street Shaw, Oldham, OL2 8AZ