Standards and Regulations

BS 7953: 1999 Entrance flooring systems – selection, installation and maintenance Cross References

BS 5325 : 2001 Installation of textile floor coverings – code of practice BS 5557 : 1992

ISO 2424 : 1992 Textile floor coverings – vocabulary

BS 8203 : 2001 Code of practice for installation of resilient floor coverings

BS 8204 : 2003 Screeds, bases and insitu-floorings. Part 1: Code of practice for concrete bases and screeds to receive insitu-floorings

DD 240 (All parts) Fire safety engineering in buildings

BS is a form of guidance and recommendation. It should not be quoted as a specification and particular care should be taken to ensure that claims of compliance are not misleading.

Building Regulations 2000 – Approved Document M “Access to and use of buildings” England and Wales

Extracts from the Building Regulations

Requirement

PART M ACCESS TO AND USE OF BUILDINGS

Access and Use

M1. Reasonable provision shall be made for people to-

a) gain access to : and

b) use the building and its facilities.

Approved Document M Provisions (Entrance Lobbies)

2 – 29 (e) Floor surface materials within the lobby do not impede the movement of wheelchairs e.g. not coir matting, and changes in floor materials do not create a potential trip hazard.

2 – 29 (f) The floor surface helps to remove rainwater from shoes and wheelchairs.

2 – 29 (g) Where matwells are provided, the surface of the mat is level with the surface of the adjacent floor finish.

Scotland

Building (Scotland) Regulations 2004 and Section 4 (Safety) of the Non-domestic and Domestic Technical Handbooks.

Northern Ireland

Building Regulations (Northern Ireland) 2000. Technical Booklet R. Access and facilities for disabled people (Dec 2000).

Information contained in this publication may be subject to Crown copyright.

Architects Specification Notes

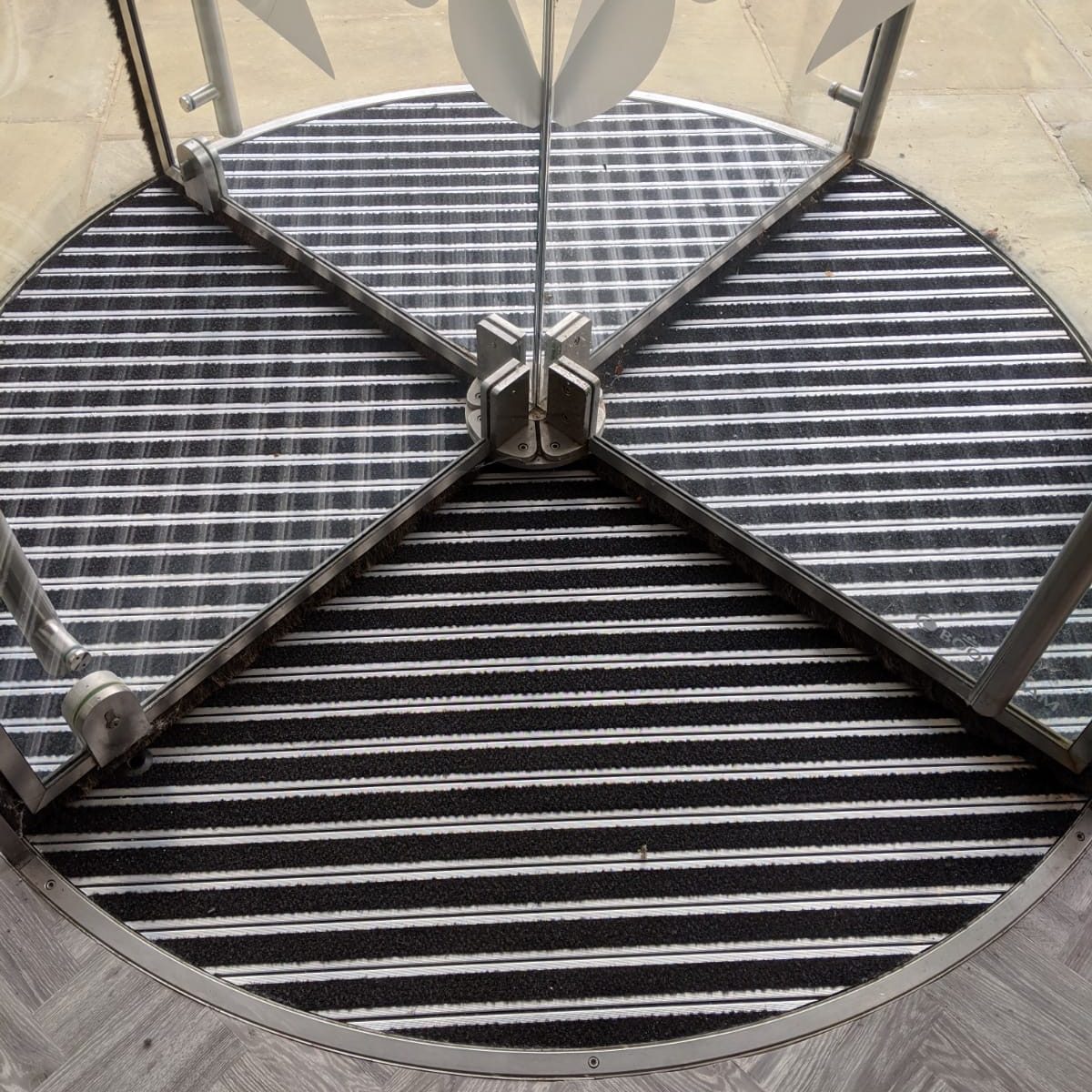

Typical installation recessed in matwell

UKM Design 17mm Entrance Matting System

Typical installation flat to floor surface

UKM Classic 12mm Entrance Matting System

How to specify UKM products

N10 General Fixtures/Furnishings/Equipment

N10/300 Entrance Matting

Manufacturer: UKMat Group (01706 843589)

Entrance Matting: UKM Design O 17mm 24 AN entrance matting system

Colour: Anthracite

Size: 2400mm x 1200mm

Frame: UKM1A 25 x 25 x 5mm mitred for site assembly

Size: 2400mm x 1200mm inside dimension

Recommendations: Plug and screw frame to recess formed in existing floor and make good, screed matwell base to correct depth to leave new matting surface level with specified floor finish.

UKM product codes

Example: UKM Design entrance matting

UKM DE O 17 24 AN

UKM UKMat Manufacturer

DE Design Product name

O Open Surface construction

17 17mm Thickness of mat

24 TN24 Wiper strip material

AN Anthracite Colour choice

Airport, rail and marine specification

Specification 3 UKM entrance flooring systems are available custom made to individual design requirements exceeding the most stringent international fire safety standards for rail and marine applications including:-

BS 6853 Class 1a:

NF F16-101 Class M1,F0

DIN 4102 Class B1

NFPA 130 and IMO Res A653(16)